Quality Inspection for Jaw Chuck For Lathe - Hydraulic Hydraulic Chuck With High Rawjaws Soft Jaws Non Standard Jaws Hard Jaws Three Jaws 90 60 120 Degrees Support Non Standard Customized Preferred Steel Corrosion Prevention More Durable – LIYUANXIN

Quality Inspection for Jaw Chuck For Lathe - Hydraulic Hydraulic Chuck With High Rawjaws Soft Jaws Non Standard Jaws Hard Jaws Three Jaws 90 60 120 Degrees Support Non Standard Customized Preferred Steel Corrosion Prevention More Durable – LIYUANXIN Detail:

Product Description

Numerical control machine tool is in accordance with the pre-programmed processing program, automatically processed parts. We put the parts of the processing craft route, process parameters and tool trajectory, displacement, cutting parameters (spindle revolutions, feeding, turning back, etc.) as well as the auxiliary function (in knife, spindle forward, reverse, cutting fluid, etc.), according to the regulations of the nc machine tool of instruction code and program format to compile processing orders, Then the contents of the program are recorded on the control medium (such as punched paper tape, magnetic tape, disk, magnetic bubble memory), and then input to the numerical control device of the CNC machine tool, so as to command the machine tool to process parts.

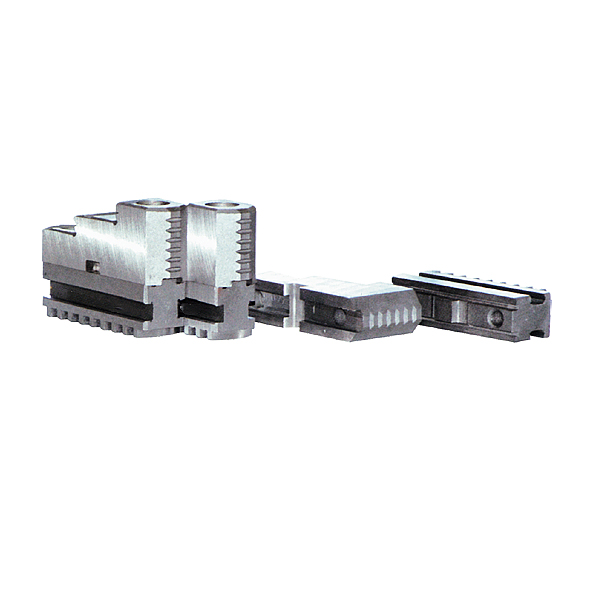

1. Custom non-standard soft claw, hard claw, chuck claw, claw, claw, claw, automatic claw, robot finger, can be designed, customized, OEM OEM.

2. Three products for one payment, one pay independent packaging. After the product is soaked in anti-rust oil, it is packed with PE bag and paper box. By default, we usually use laser typewriter to mark numbers like 1,2,3 for convenience. We can also mark them according to the requirements of the customer’s drawings. If it is not necessary to lettering, it needs to be explained in advance.

3. The product can also be divided into two one pay, four one pay, six one pay and so on according to the customer chuck model.

Product Parameters

| Origin | Jiangsu, China |

| Suitable machine | Precision milling machine |

| Material | High quality steel |

| Treatment | Vacuum heat treatment |

| Application | CNC lathe machine, machining center, various precision machine tools |

| Usage | Versatile |

| Features | High precision |

Our Service

Our company’s commitment:

1. We reply to customer inquiry within 24 hours.

2. We will check carefully before shipment and choose strong packing to ensure no damage in transit.

3. Once you have quality problems, you can contact us at any time, and we will actively help you deal with them.

Product detail pictures:

Related Product Guide:

All we do is usually connected with our tenet Customer to start with, Rely on initial, devoting on the food packaging and environmental protection for Quality Inspection for Jaw Chuck For Lathe - Hydraulic Hydraulic Chuck With High Rawjaws Soft Jaws Non Standard Jaws Hard Jaws Three Jaws 90 60 120 Degrees Support Non Standard Customized Preferred Steel Corrosion Prevention More Durable – LIYUANXIN , The product will supply to all over the world, such as: Liverpool, Jamaica, Finland, we sincerely hope to establish a good and long-term business relationship with your esteemed company through this opportunity, based on equality, mutual benefit and win-win business from now to the future. Your satisfaction is our happiness.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.